10 Types of Hand Cutting Tools

June 27th 2025

On any construction site, precision, efficiency, and safety are non-negotiable. While power tools grab the headlines, the true workhorses often remain the humble hand tools. Understanding the different types of hand cutting tools is fundamental in correctly shaping, trimming, and fitting materials. We aren't just talking about anything with a blade; we mean the specific instruments designed for specific, demanding tasks in construction.

Understanding 10 Types of Hand Cutting Tools Every Professional Needs

In this blog, we explore 11 essential hand cutting tools that form the backbone of any professional's kit, and discover how we can equip you with the best. So, let's begin.

1. Utility Cutters

Let's start with a classic. The utility knife is arguably the most common and versatile cutting tool on any job site, whether a construction site or otherwise. But don't let its ubiquity fool you; a good utility knife is a precision instrument in the right hands.

What is it?

A knife with a sharp, typically replaceable blade, often housed in a retractable body for safety and convenience. The blade itself is usually trapezoidal or hooked.

Why are they essential in construction?

Think about the sheer volume of packaging you open on a construction site – rolls of insulation, boxes of nails, sheets of plastic sheeting, bundles of material.

A utility knife tears through these effortlessly. Beyond packaging, you use it to score drywall before snapping, trim excess material like roofing felt or vapour barrier, shape insulation bats, or clean edges. Its compact size means you can always keep one handy in your pocket or tool belt.

Key Features & Variations

- Retractable Blades: The most popular style. You push a slider to extend or retract the blade, significantly reducing the risk of accidental cuts when not in use.

- Fixed Blades: Offer more rigidity for tougher cuts but require a sheath for safety.

- Blade Storage: Many models include internal storage for spare blades, eliminating the need to search for replacements during tasks.

- Ergonomic Handles: Modern utility knives feature comfortable, non-slip grips, essential when using the tool all day. Materials range from durable plastic to metal alloys.

- Blade Change Mechanism: Look for tools with quick, tool-free blade changes. Time is money on site!

- Specialised Blades: You aren't limited to the standard straight blade. Hook blades are fantastic for cutting roofing materials or vinyl flooring without damaging the substrate underneath. Serrated knives can handle tough, fibrous materials.

Top Products

We understand the importance of a reliable utility knife, so we stock top-tier brands. Explore robust options like the Stanley FatMax Retractable Utility Knife. We also offer great value and performance with products like Total Utility Knives and reliable choices from Deli Toolz. We've got models with quick-change blades, ergonomic grips, and built-in storage—everything you need for constant cutting tasks.

2. Aviation Snips

When you need to cut through sheet metal with control and precision, standard scissors just won't cut it (literally). That's where aviation snips, sometimes called tin snips, come into play. They are a specific type of shear designed with leverage in mind.

What are they?

Heavy-duty scissors featuring compound leverage (multiple pivot points) and often serrated jaws, specifically designed for cutting sheet metal, flashing, and other thin metallic materials.

Why are they essential in construction?

HVAC installers rely on them constantly to shape ductwork and sheet metal fittings. Roofers use them for cutting flashing and sometimes even certain metal roofing panels. Light-gauge steel framing requires snips for cutting studs and track. Electricians use them for cutting metal conduits or boxes.

Key Features & Variations

- Compound Leverage: This is the defining feature, significantly amplifying the force applied to the handles to easily cut through metal.

- Serrated Jaws: The small teeth on the cutting edges grip the metal, preventing it from slipping out of the jaws while you cut.

- Colour Coding: A standard system identifies the cutting direction:

- Yellow Handles: Straight cuts. The most common type is versatile for straight lines or gentle curves.

- Red Handles: Left-cutting snips. The blades are offset to the right, allowing you to make cuts curving to the left in sheet metal without the tool body interfering. Ideal for cutting circles or curves.

- Green Handles: These are right-cutting snips. The blades are offset to the left, perfect for making cuts curving to the right.

- Offset vs. Straight Blades: Some snips have blades offset from the handles, allowing you to cut in the middle of a large sheet without dramatically bending the material.

Top Products

For reliable metal cutting, you need aviation snips built to last. We supply top brands like Total Aviation Snips, which are known for their durability and performance. Find versatile Stanley Aviation Snips and precision-engineered options from Sata Tools in our collection. We stock all colour-coded varieties, so you always have the right tool for straight lines and left or right curves.

3. The Pipe Cutters

Cutting pipe accurately and cleanly is critical for plumbing, HVAC, and electrical work. A ragged, crooked cut can lead to leaks or improper fittings. A dedicated pipe cutter shines in this area, providing a smooth, perpendicular cut far superior to a hacksaw for many materials.

What is it?

A tool designed to cut pipes (metal or plastic) by rotating a cutting wheel around the pipe while applying pressure.

Why are they essential in construction?

Plumbers use them daily for copper, PEX, and PVC pipes. Electricians need them for EMT and rigid conduit. HVAC technicians might use them for copper refrigerant lines. They create a clean, straight cut that minimises burring and prepares the pipe perfectly for fittings.

Key Features & Variations

- Metal Pipe Cutters: Typically use a sharp, hardened steel cutting wheel. Adjustable jaws or rollers hold and guide the pipe while you rotate the cutter. Sizes vary greatly depending on the pipe diameter they accommodate. Some have a deburring tool attached for cleaning the inside edge of the cut pipe.

- Plastic Pipe Cutters (PVC/PEX Cutters): Often use a ratchet mechanism and a sharp blade to slice through plastic pipe. They offer incredible speed and ease for softer plastics like PVC, PEX, and PEX-AL-PEX. These are usually less messy than sawing.

- Mini or Close-Quarters Cutters: Designed for tight spaces where a standard-sized cutter won't fit. Essential for renovations or working in cramped mechanical rooms.

Top Products

Achieve professional-grade pipework with our selection of high-quality pipe cutters. We feature reliable options from SATA that are perfect for various pipe materials and sizes. You can also find durable and efficient Total Pipe Cutters designed for demanding use. We have the right cutter from copper to PVC to ensure leak-free connections.

4. Cutting Nippers

Often overlooked, cutting nippers are specialised pliers explicitly designed for cutting wires, nails, rivets, or small metal rods flush with a surface. They are invaluable for detailed trimming and removing fasteners.

What are they?

Pliers with hardened cutting jaws positioned at an angle are designed for cutting small metal objects, often close to a surface.

Why are they essential in construction?

Electricians use them constantly for cutting wires. Fencing contractors need them for wire mesh and ties. Tilers might use them to trim wire lath. Carpenters use them to cut nails or screws that are sticking out. Rebar workers use them for wire ties.

Key Features & Variations

- End Cutting Nippers: The jaws are perpendicular to the handles, allowing you to cut objects flush or very close to a surface (like clipping off a nail head or the end of a wire tie).

- Side Cutting Pliers (Diagonal Cutters): The jaws are parallel to the handles, designed for cutting wires or small fasteners away from a surface. We'll touch on end-cutting pliers specifically later, but side cutters are also a vital part of the nipper family.

- Hardened Jaws: The cutting edges are heat-treated to withstand cutting metal wires and nails without dulling quickly.

- Handle Length: Longer handles provide more leverage for cutting thicker materials.

- Insulated Handles: Crucial for electricians working with live wires (though power should always be off when working on circuits).

Top Products

Precision wire and fastener cutting requires quality nippers. Our selection includes durable options from brands like Sata Tools, which are known for their quality hand tools. Find reliable performance with Knipex Cutting Nippers, which is perfect for everyday use on-site. We offer various sizes and types to meet specific needs, including side and end-cutting options.

5. Blade Knife

While the utility knife is king for replaceable blades, other knives serve critical functions. This category can include folding knives, fixed-blade knives, or specific trade knives (like a roofer's knife or insulation knife) that don't fit the standard "utility knife" mould but are nonetheless hand cutting tools professionals use.

What is it?

A general term for knives with a fixed or folding blade, often with a point, used for piercing, slicing, and general cutting tasks.

Why are they essential in construction?

A robust blade knife is helpful for heavier-duty tasks that might be too demanding for a standard utility knife. Think cutting rope, scoring thick materials, carving, stripping cable insulation (with care), or simply having a sharp edge always available for miscellaneous needs.

Key Features & Variations

- Fixed Blade: Offers maximum strength and rigidity. Requires a sheath. Blade lengths and shapes vary greatly depending on the intended use.

- Folding Blade: Provides portability and safety when closed. Locking mechanisms (liner lock, frame lock, back lock) are crucial for safe use. One-hand opening features are standard.

- Blade Material: High carbon steel holds an edge well but can rust; stainless steel resists rust but may require more frequent sharpening.

- Handle Material: Ranges from durable synthetics to metal, providing grip and longevity.

- Specialised Designs: Roofing knives with hooked or curved blades, insulation knives with long, serrated edges, etc.

Top Products

We have covered those tasks requiring a more traditional or heavy-duty blade. Explore versatile options like Milwaukee FASTBACK Utility Knife, known for their quick opening and durable construction. We also offer fixed blade options from reputable brands that are suitable for various construction needs.

6. End Cutting Pliers

While mentioned briefly under nippers, End Cutting Pliers deserve their spot due to their specific application: cutting material flush or as close as possible to a surface. These are distinct from side-cutting pliers (diagonal cutters).

What are they?

Pliers with cutting jaws located at the very end of the head are designed to make cuts parallel to the surface on which the handles are resting.

Why are they essential in construction?

Carpenters use them extensively for pulling and cutting nails. Rebar workers use them to twist and cut wire ties tightly against the rebar. Fencing contractors use them for wire. They are the go-to tool for snipping off anything sticking out slightly from a surface.

Key Features & Variations

- Jaw Shape: The flat back of the jaws allows them to sit flush against a surface. The cutting edges are on the front edge.

- Leverage: Designed to provide significant leverage right at the jaws.

- Hardened Jaws: Essential for cutting through nails, screws, and various wires.

- Handle Grip: Comfortable handles improve grip and force transfer.

Top Products

You need quality end-cutting pliers for flush cuts and effective nail pulling. We offer durable and reliable options from brands like SATA, which are built to withstand harsh job site conditions. Explore our range to find the right size and leverage for your needs.

7. The Hacksaw

The hacksaw is a timeless solution for cutting metal, plastic, or even wood in a straight line when power tools aren't suitable or available. It's a manual saw with a fine-toothed blade held under tension in a frame.

What is it?

A handsaw, consisting of a frame with a narrow, disposable blade under tension, is used to cut materials such as metal, plastic, and sometimes wood.

Why are they essential in construction?

Plumbers use them for cutting pipes (though pipe cutters are often preferred for cleaner cuts). Electricians cut conduit (EMT, PVC). Metal fabricators on-site cut angle iron or bar stock. General contractors might use them to cut bolts and rebar (with a suitable blade) or make precise trim or mould cuts where a power saw is impractical.

Key Features & Variations

- Frame: Provides tension to the blade. It can be fixed or adjustable (allowing for different blade lengths). Some frames will enable the blade to be mounted at various angles for flush cuts.

- Blade: The crucial part. Hacksaw blades have small teeth and are typically made of high-speed steel (HSS) or bi-metal (combining HSS teeth with a flexible spring steel back).

- Teeth Per Inch (TPI): This is critical. Higher TPI (24, 32) is for smoothly cutting thin metals and plastics. Lower TPI (10, 14, 18) is for thicker metals, angle iron, or wood. Match the TPI to the material thickness – you always want at least three teeth in contact with the material.

- Handle: Ergonomic handles improve comfort and control during long cuts.

Top Products

A reliable hacksaw is a must-have for any serious toolkit. We offer durable frames and high-performance blades from trusted brands like Stanley Hacksaws and Total Hacksaws. We stock various blade types and TPI counts so you can tackle any material effectively.

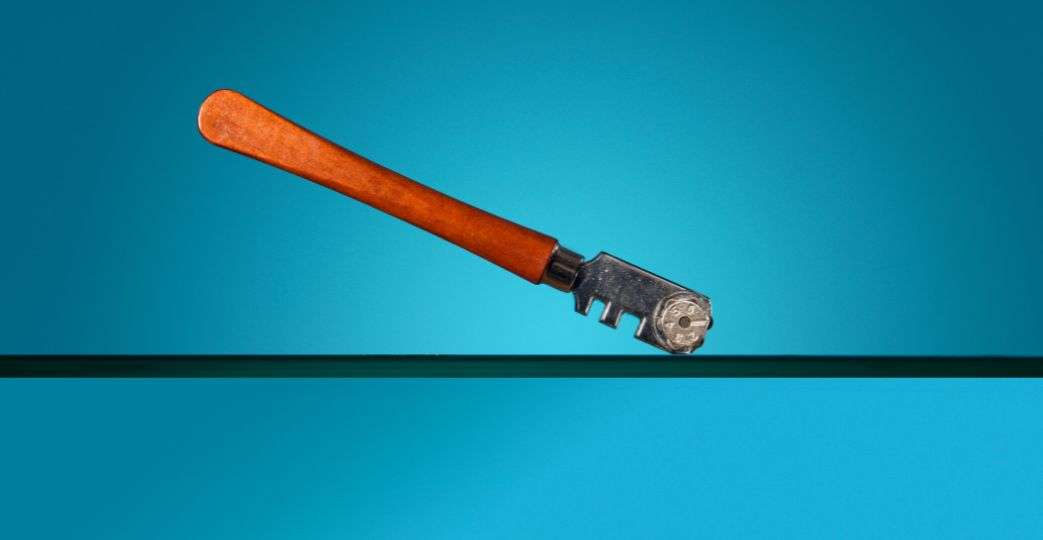

8. Glass Cutter

Working with glass requires a specialised tool that scores the surface rather than cutting straight through. A glass cutter creates a controlled fracture line, allowing you to snap the glass cleanly.

What is it?

A hand tool with a small, hardened wheel or diamond tip is used to score a line on the surface of glass or tile, allowing the material to be broken cleanly along the score.

Why are they essential in construction?

Glaziers use them constantly to size window panes, mirrors, and tabletops. Tilers use similar tools for scoring ceramic or porcelain tiles before snapping them with a tile breaker. Anyone needing to install custom-sized glass or mirrors on-site needs a reliable glass cutter.

Key Features & Variations

- Cutting Wheel: Typically made of hardened steel or tungsten carbide. The quality of the wheel is paramount for a clean score. Some cutters have multiple wheels on a turret.

- Handle: Can be wood, plastic, or metal. Some feature a reservoir handle designed to hold cutting oil, which helps lubricate the wheel and produces a smoother score.

- Tip: Some cutters use a small industrial diamond tip instead of a wheel, often preferred for precise or delicate work.

- Ball End: Many glass cutters have a small metal ball on the end of the handle, which is used for tapping the glass underneath the score line to help start the fracture.

Top Products

Working with glass requires precision and the right tool. We offer high-quality Glass Cutters designed for clean, reliable scoring. Look for cutters with durable tungsten carbide wheels for long-lasting performance on your glazing and tiling projects.

9. Snap-Off Knife

Distinct from the standard utility knife, the snap-off knife offers a continuous supply of sharp points on a segmented blade. When the tip gets dull, you snap it off to reveal a new, razor-sharp point.

What is it?

A knife with a long, segmented blade where the tip of the blade can be snapped off along scored lines to provide a fresh, sharp cutting edge.

Why are they essential in construction?

They are fantastic for tasks requiring a consistently sharp, fine point, like trimming wallpaper, cutting thin plastic sheeting, scoring delicate materials, or detailed trimming work. Their blades are usually thinner than utility knife blades, allowing for more flexible or intricate cuts.

Key Features & Variations

- Segmented Blade: The defining feature, with multiple break-off points. Standard widths are 9mm, 18mm, and 25mm.

- Blade Advancing Mechanism: A slider allows you to extend the blade incrementally and lock it in place.

- Built-in Blade Snapper: Most snap-off knives have a cap at the end designed to safely snap off the dull blade segment.

- Handle Material: Ranges from basic plastic to more robust metal or reinforced composite for heavier-duty versions.

- Blade Material: Typically carbon steel or stainless steel. Black blades are often carbon steel treated for extra sharpness.

Top Products

For tasks needing a consistently sharp, fine point, snap-off knives are the answer. We stock a wide range of reliable total snap-off knives and versatile options from SATA Tools. Find various blade widths and durable handles perfect for everything from light trimming to more demanding tasks.

10. PVC Cutter

While a pipe cutter can handle PVC, a dedicated PVC cutter (often included under the broader "Pipe Cutter" category but distinct in mechanism) is typically faster and simpler for plastic pipe only. These use a sharp blade and a ratchet mechanism to slice cleanly through the plastic.

What is it?

A plier-like tool with a sharp, curved blade that closes against a curved anvil, specifically designed to cut plastic pipes like PVC, CPVC, and PEX using a ratcheting action.

Why are they essential in construction?

Plumbers and irrigation specialists use them constantly to cut schedules 40 or 80 PVC, CPVC for hot water lines, and PEX tubing. Electricians use them for cutting PVC conduit. They provide a clean, perpendicular cut much faster than a saw and with no messy sawdust.

Key Features & Variations:

- Ratcheting Mechanism: You can apply pressure incrementally by squeezing the handles repeatedly, making it easy to cut through even thick-walled pipe with little effort.

- Sharp Blade: A hardened steel blade is crucial for a clean slice without deforming the pipe.

- Curved Anvil: Supports the pipe and helps guide the blade for a square cut.

- Locking Mechanism: Keeps the cutter closed for safe storage.

- Capacity: Available in various sizes to cut pipes up to specific diameters (e.g., 1", 1 1/2", 2", 3").

Top Products:

A good PVC cutter is indispensable for fast, clean cuts on all your plastic pipe needs. We feature high-quality PVC Cutters from brands like SATA and Total Tools. Find a range of sizes and robust designs that make light work of plastic pipe on site.

Quick Reference Table: 10 Essential Hand Cutting Tools for Construction

We've compiled this handy reference chart to help you quickly recall the purpose and key features of the essential types of hand cutting tools we've covered. Keep this in mind as you build your professional toolkit!

| Tool Name | Primary Use | Key Application in Construction | Distinguishing Feature |

| 1. Utility Cutter | General cutting and scoring | Opening packages, scoring drywall, trimming insulation/membranes. | Retractable or fixed blade, accepts various blade types. |

| 2. Aviation Snips | Cutting thin sheet metal | Cutting HVAC ductwork, flashing, and light-gauge steel framing. | Compound leverage, often colour-coded for cut direction. |

| 3. Pipe Cutter | Cutting metal or plastic pipe | Sizing copper, PEX, or EMT conduit for plumbing & electrical. | Rotates around the pipe with a cutting wheel (metal) or slices with a blade (plastic). |

| 4. Cutting Nippers | Cutting wire, nails, and small metal | Trimming rebar tie wire, cutting electrical wires, and clipping nails. | Pliers with hardened jaws for cutting. |

| 5. Blade Knife | General-purpose/heavy-duty cuts | Cutting rope, stripping cable (with care), carving, and piercing. | Fixed or folding blade, designed for robustness. |

| 6. End Cutting Pliers | Cutting flush to a surface | Cutting nails/screws flush, trimming rebar ties close to surface. | Cutting jaws are at the end, parallel to the gripping plane. |

| 7. Hacksaw | Cutting metal, plastic, and wood | Sizing metal conduit/pipe, cutting bolts, rebar, and plastic pipe. | The frame holds a tensioned, fine-toothed replaceable blade. |

| 8. Glass Cutter | Scoring glass or tile | Cutting glass panes, mirrors, and scoring ceramic/porcelain tiles. | Small, hardened wheel or diamond tip scores the surface. |

| 9. Snap-Off Knife | Precise cutting with a fresh tip | Trimming wallpaper, cutting thin plastics, and detailed light work. | Segmented blade allows snapping off dull tips. |

| 10. PVC Cutter | Cutting plastic pipe quickly | Sizing PVC, CPVC, and PEX pipes for plumbing and electrical conduit. | Sharp blade and ratchet mechanism slice through plastic. |

Frequently Asked Questions (FAQs)

Q. How often should I replace utility knife blades?

Replace the blade when you feel it dragging or requiring excessive force. A sharp blade is safer and more efficient.

Q. Can I use aviation snips to cut thicker metal?

No, aviation snips are designed for thin sheet metal. Using them on thicker material can damage the jaws. Use a hacksaw or metal shear for thicker stock.

Q. What's the main difference between standard utility and snap-off knives?

A standard utility knife uses a single, thicker blade that you replace when dull. A snap-off knife has a segmented blade that you break off piece by piece to get a fresh, sharp tip.

Q. Can one pipe cutter cut all types of pipe?

Not typically. Pipe cutters are usually material-specific (metal like copper/steel vs. plastic like PVC/PEX) and size-specific. Choose the right cutter for the pipe material and diameter.

Q. How do I choose the right hacksaw blade?

Match the Teeth Per Inch (TPI) to the material thickness. Use higher TPI (24-32) for thin materials and lower TPI (10-18) for thicker materials. Ensure at least three teeth are in contact with the material.

Q. Are insulated cutting nippers safe for cutting live wires?

While insulated handles offer a layer of protection, you should never attempt to cut live electrical wires. Always shut off the power supply before working on electrical circuits.

Q. What safety gear is most important when using hand cutting tools?

Safety glasses or goggles are crucial for nearly all cutting tools to protect from flying debris. Gloves are also highly recommended, especially when handling sharp blades or cut materials.

Final Words

The first step is understanding the 10 types of hand cutting tools we've discussed today. The next step is getting them into your hands. We have meticulously curated a vast selection of these essential cutting tools from the world's leading brands.

We make browsing by tool type or brand easy, compare features, and get the right tools delivered directly to your job site or workshop. Stock your toolbox with the right types of hand cutting tools and experience the difference they make on every project.

We encourage you to explore becoming a FEPY PRO member. With a PRO membership, you unlock exclusive benefits. Imagine getting special pricing, early access to new tool arrivals, priority support, and other perks that help you save time and money on the tools and materials you need daily. Get it now.