What is Rebar in Construction? | Types & Sizes

April 26th 2025

Concrete builds the constructions, and it is strong in compression. But it's weak under tension – it cracks when pulled or bent. To make concrete structures truly resilient, we add steel. That's what is rebar in construction: the steel reinforcement provides concrete's vital tensile strength. It's fundamental to every beam, column, and slab you build.

Understanding rebar types and sizes is non-negotiable for contractors, builders, architects, and DIYers. So, let's explore exactly what is rebar in construction, why it's indispensable, the different types and sizes you encounter, and how we help you get the right materials for your job.

Why Concrete Needs Rebar?

Imagine building something solid. You immediately think of concrete, right? It's a liquid stone that is incredibly versatile, and when it cures, it becomes incredibly hard. You can stand on a concrete slab and pile heavy objects on it, and it resists being crushed (compression) with impressive force.

But what happens if you try to bend or pull that slab apart? Think of a long concrete beam supporting a floor. The top of the beam is compressed, but the bottom is stretched or put under tension.

Similarly, the wind pushing against a concrete wall creates bending moments, tensioning one side. Concrete cracks when subjected to significant tensile stress. It lacks the fibrous, interlocking strength needed to resist pulling forces.

This is the critical gap that steel rebar fills. Steel, used explicitly for rebar, possesses incredibly high tensile strength. It resists being pulled apart or stretched without breaking. We create a composite material- reinforced concrete by embedding steel rebar within the concrete in the areas where tension will occur.

The concrete handles the compression, and the steel rebar handles the tension. They work together synergistically to create structures that are far stronger and more durable than either material could be on its own.

So, when you ask what is rebar in construction, the most straightforward answer is that the steel reinforcement gives concrete its tensile strength, enabling it to resist bending, cracking, and, ultimately, failure under various loads and forces.

We embed it wherever concrete is expected to experience tension – in foundations, columns, beams, slabs, walls, bridges, tunnels, and virtually every significant concrete structure you can imagine.

What is Rebar in Construction: Key Purpose

Now that we understand why we need it, let's look at the material. A reinforcing bar, short for reinforcing bar, is typically made from carbon steel. It comes in lengths of bars or rolls of wire and is explicitly designed for reinforcing concrete.

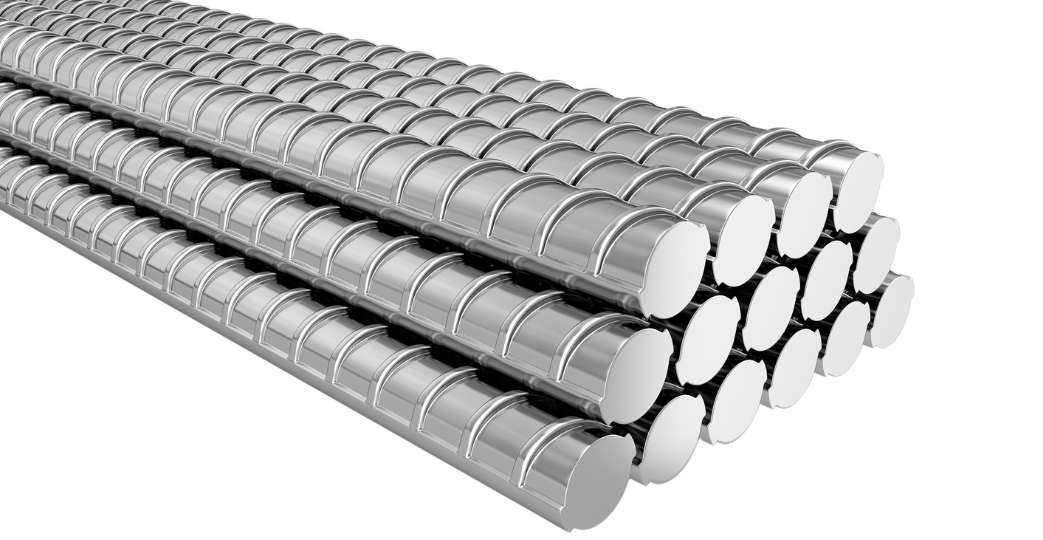

The most distinctive feature of rebar, and something you'll notice immediately when you see it on any construction site or in our yard, is the ridges or deformations running along its surface.

These deformations aren't just for show. They are absolutely crucial! They create a mechanical bond with the concrete as it cures. When the concrete hardens around the deformed rebar, the ribs lock the steel in place.

This prevents the rebar from slipping within the concrete when subjected to tensile forces, ensuring the stress is effectively transferred between the two materials. Without these deformations, the rebar couldn't grip the concrete properly, and the reinforced concrete wouldn't achieve its intended strength.

Exploring the Types of Rebar

While the core function of rebar – providing tensile strength to concrete – remains constant, the specific demands of different projects and environments necessitate various types of rebar.

The choice often comes down to balancing strength, corrosion resistance, cost, and specific project requirements. We understand these nuances, and we stock the types you need for the UAE's diverse construction landscape.

Let's look at the common types we encounter and supply:

1. Deformed Black Rebar (Carbon Steel Rebar)

This is the most common and widely used type of rebar globally and right here in the UAE. Standard carbon steel bars with characteristic deformations. Its colour is typically dark grey or black due to the mill scale from the manufacturing process.

It offers an excellent strength-to-cost ratio and bonds very well with concrete thanks to its deformations. It's suitable for most general concrete reinforcement applications where corrosion isn't a primary concern or adequate concrete cover provides sufficient protection.

Foundations, columns, beams, standard slabs, and walls in buildings where they aren't directly exposed to harsh corrosive elements like saltwater spray or aggressive chemicals.

When exposed to moisture and oxygen, carbon steel is susceptible to rust (corrosion). Rust can form if the concrete cover is insufficient or cracks develop, allowing corrosive agents to reach the rebar.

Rust occupies more volume than steel, causing the concrete to spill (break off) and severely weakening the structure. This is a significant consideration, especially in the coastal and humid climate of the UAE.

2. Epoxy-Coated Rebar

Standard black rebar that receives a protective coating of fusion-bonded epoxy resin. The epoxy is applied electrostatically and then cured, creating a formidable, impermeable barrier.

The primary purpose of the epoxy coating is to protect the underlying steel from corrosion. It acts as a barrier against moisture, chlorides (like those from sea salt or de-icing salts, although de-icing salts are less common here, coastal environments are highly relevant), and other corrosive substances.

Projects in aggressive environments, particularly those exposed to saltwater or marine conditions, bridge decks, parking garages, and structures requiring enhanced durability against corrosion. Given the UAE's significant coastline and often high humidity, epoxy-coated rebar is vital for many structural applications.

While excellent at preventing corrosion, the epoxy coating can be damaged during handling, cutting, and bending. Any break in the coating exposes the underlying steel, potentially creating a site for localised corrosion. Proper care during installation is crucial.

3. Galvanized Rebar

Standard rebar coated with a zinc layer through a hot-dip galvanizing process. The steel bars are immersed in molten zinc.

Like epoxy coating, galvanization provides corrosion resistance. Zinc protects the steel in two ways: it acts as a barrier. It offers sacrificial protection (the zinc corrodes before the steel does if the coating is scratched).

Similar applications to epoxy-coated rebar where enhanced corrosion resistance is needed, such as coastal structures areas with exposure to de-icing salts (less common in UAE but relevant globally) or specific industrial environments.

Galvanized rebar can be more expensive than black rebar. While less susceptible to damage than epoxy coatings, the galvanizing process can sometimes slightly affect the bond strength with concrete, although standards account for this.

4. Stainless Steel Rebar

Rebar is made from stainless steel alloys containing chromium and nickel.

This is the premium choice for corrosion resistance. Stainless steel forms a passive oxide layer that is highly rust-resistant, even in extremely aggressive environments. It offers superior durability and requires minimal concrete cover compared to carbon steel options.

Critical infrastructure projects, structures in highly corrosive environments (like offshore platforms or elements directly exposed to harsh chemicals), prestigious buildings with long design lives, or areas where repair is difficult or costly.

Stainless steel rebar is significantly more expensive than carbon steel, epoxy-coated, or galvanized options. This cost often limits its use to projects where its specific properties are absolutely essential.

Understanding the Steel Grades

Beyond the protective coating or alloy type, rebar is also specified by its strength, known as its steel grade. The grade indicates the minimum yield strength of the steel – the point at which it begins to deform permanently under tension.

In the UAE, we typically use the metric system and rebar strength is often specified in megapascals (MPa). A standard grade you'll encounter is Grade 420 MPa. This means the steel has a minimum yield strength of 420 megapascals.

You might also hear this referred to in imperial units as Grade 60, roughly equivalent (60,000 pounds per square inch).

Higher grades, like 500 MPa or even higher, offer increased strength. Structural engineers carefully select the appropriate grade based on the design loads the structure must bear.

Using a grade lower than the specified one compromises the structural integrity. We ensure the rebar we supply meets the specified grade requirements for your project plans.

Understanding Rebar Diameters

Just as important as the type and grade is the size of the rebar. Rebar sizes are specified by their nominal diameter. A larger diameter bar can carry more tensile load than a smaller one made of the same steel grade.

In the UAE and most metric countries, we refer to rebar sizes by their diameter in millimetres (mm). Standard sizes you'll regularly work with include:

- 8 mm: Often used for stirrups (the closed loops that reinforce beams and columns against shear forces) or light mesh reinforcement.

- 10 mm: Common for lighter slabs, footings, and secondary reinforcement.

- 12 mm: A versatile size widely used for primary reinforcement in footings, beams, columns, and slabs.

- 16 mm: Used for heavier loaded beams, columns, and thicker slabs.

- 20 mm, 25 mm, 32 mm and larger: Reserved for substantial structural elements like large columns, deep beams, heavy foundations, bridges, and high-rise building cores where significant loads are anticipated.

Structural engineers calculate and specify the exact size and spacing of rebar required for each structure part based on anticipated loads, concrete strength, and building codes.

Decoding Rebar Accessories

While the rebar bars are the main characters, they cannot perform their job effectively without a crucial supporting cast: rebar accessories. These seemingly small components ensure the rebar cage is correctly assembled, positioned, and protected within the concrete. We see these as essential tools, not optional extras.

Here are some key accessories and why we insist you use them:

1. Tie Wire

It is Soft, annealed steel wire, typically sold in rolls. Workers use tie wire to secure the intersections of rebar bars, tying the complex network of reinforcement bars together into a rigid "cage" or mat before the concrete pour. This prevents the bars from shifting out of position during the concrete placement.

A rebar cage that shifts means the reinforcement isn't in the right place to handle the tension, potentially weakening the structure. Tie wire ensures the designed geometry is maintained.

2. Rebar Chairs and Spacers

What they are: Small supports, usually made of plastic, wire, or concrete, with different shapes and heights.

These accessories lift and hold the rebar cage at the correct height within the concrete formwork, ensuring the required amount of concrete surrounds the rebar. This surrounding concrete layer is called "concrete cover."

Adequate concrete cover is paramount. It protects the steel from moisture and corrosive agents, preventing rust. It also provides fire resistance, delaying heat transfer to the steel in case of a fire, which could weaken the rebar and cause structural collapse. Spacers ensure this vital cover is consistently achieved.

3. Rebar Couplers

Mechanical devices are used to join two lengths of rebar together end-to-end.

Couplers provide an alternative to traditional lapping (overlapping two bars for a certain length to transfer stress). They create a strong, reliable connection that can save on material (less overlap needed) and reduce rebar congestion in heavily reinforced areas.

Proper splicing is crucial for transferring tensile forces along the length of the bar. Couplers offer a robust, engineered solution, particularly valuable for larger-diameter bars or critical connections.

4. Safety Caps

Brightly coloured plastic caps are placed over the exposed ends of the vertical rebar. Construction sites have inherent risks. Exposed rebar ends are sharp and can cause serious impalement injuries if someone falls onto them. Safety caps cover these ends, mitigating this risk.

Site safety is non-negotiable. Safety caps are a simple, effective way to prevent severe accidents. These accessories aren't minor details but integral components ensuring the rebar system functions as designed. Using high-quality accessories is just as important as using the correct rebar.

Understanding Remesh

While individual rebar bars form the backbone of many structures, different steel reinforcement is sometimes more suitable, particularly for large, relatively thin concrete sections like slabs-on-grade pathways, driveways, or curtain wall panels. This is where Remesh, also known as welded wire fabric or welded wire mesh, comes into play.

Remesh is a grid of steel wires welded together at their intersections. It comes in various wire gauges (thicknesses) and grid sizes (spacing between wires). You'll typically find it in large, flat sheets or rolls.

So, how it differs from Rebar? While both are steel reinforcement, Remesh is a prefabricated grid rather than individual bars that you cut, bend, and tie on-site.

Remesh provides efficient, consistent reinforcement over large areas. It's particularly effective at controlling concrete cracking caused by shrinkage during curing and temperature changes. It's faster to lay down than tying individual bars for specific applications.

Ground slabs for houses, warehouses, patios, sidewalks, driveways, precast wall panels, and sometimes as shear reinforcement in walls.

Remesh serves a similar purpose to rebar, providing tensile strength and crack control. Still, its form factor makes it the preferred choice for specific applications. It's another essential form of steel reinforcement we provide, offering ease of installation and adequate performance for slab work and similar uses.

Why Trust FEPY for Your Steel Reinforcement in the UAE?

So, you understand what is rebar in construction, the different types and sizes available, the importance of accessories, and where Remesh fits in. Now, where do you go to source these critical materials for your next project here in the UAE?

This is where FEPY comes in. As a leading e-commerce store for construction materials and tools in the UAE, we have made it our mission to provide easy access to everything you need, from the most significant structural components to the smallest accessories. We understand the demands of the construction industry – the need for quality, reliability, availability, and efficient delivery.

We offer a comprehensive range of steel reinforcement products to meet the diverse needs of contractors, builders, architects, and DIY enthusiasts across the Emirates.

Ready to reinforce your structure with confidence? We make it simple:

- Looking for specific diameters and grades of reinforcing bars? Explore our extensive Rebar selection today! We stock a wide range to match your project's structural requirements.

- Planning a concrete slab, pathway, or wall? Find the perfect Remesh for your project to ensure crack control and efficient reinforcement.

- Do you need the crucial components that hold it all together and ensure proper placement and protection? Browse our essential Rebar Accessories, including tie wire, chairs, spacers, couplers, and safety caps.

We consolidate your needs, offering competitive pricing, the convenience of online ordering, and reliable delivery directly to your site. We stand ready to be your trusted partner in construction material supply.

Frequently Asked Questions (FAQs)

Q. What is the main difference between different rebar sizes?

Different sizes indicate the rebar's diameter. Larger diameter rebar can handle higher tensile loads. Structural engineers specify sizes based on the strength needed for each structure part.

Q. Why does rebar have those bumps or ribs (deformations) on its surface?

These deformations create a strong mechanical bond with the concrete. Once the concrete hardens, it prevents the rebar from slipping, ensuring the steel effectively transfers and handles tensile forces.

Q. What is "concrete cover", and why is it essential when using rebar?

Concrete cover is the layer of concrete between the rebar and the structure's surface. It's crucial for protecting the steel from moisture and corrosive substances (preventing rust) and providing fire resistance.

Q. Can I mix different types of rebar (e.g., black rebar and epoxy-coated) in the same structural element?

Generally, you should not mix different rebar types within the same element unless the structural engineer specifically designs and allows for it. Other types have varying properties that affect performance.

Q. What is the difference between Rebar and Remesh (Welded Wire Fabric)?

Rebar refers to individual steel bars cut, bent, and tied into cages for structural elements like beams and columns. Remesh is a prefabricated grid of welded wires primarily used for reinforcing flat areas like concrete slabs to control cracks.

Q. Are rebar accessories like chairs, spacers, and tie wire truly necessary?

Yes, they are essential. Accessories hold the rebar correctly within the formwork, ensuring proper concrete cover. This precise placement is vital for the rebar to function as designed and for the overall structural integrity.

Q. How do I know what size and type of rebar I need for my project?

A qualified structural engineer determines the specific size, type, and grade of rebar needed based on the structure's design, expected loads, and building codes. This information is detailed in your project's structural drawings and specifications.

Final Words

Rebar is far more than just steel rods; it is the essential tensile partner to concrete, the backbone of modern construction, and a non-negotiable element for structural integrity and safety. Understanding what is rebar in construction, its various types, appropriate sizes, and the vital role of accessories empowers you to make informed decisions that lead to safer, more durable structures.

We take pride in supplying the materials that build the UAE. We understand the challenges you face on-site and are committed to providing the quality steel reinforcement and accessories you need precisely when needed. From foundational elements to finishing touches, we are your go-to source for construction materials and tools online in the UAE.

Don't leave the strength of your structure to chance. Trust in quality materials and a reliable supplier. We are here to help you build strong, build safe, and build to last.